I read about LED lights on the sohc4.net forums and bought some bulbs through superbrightleds.com.

Not long ago, guys were figuring out complicated ways to get led lights working in their gauges and pilot boxes. The hardest part was adapting a bulb to fit the wiring harness.

This is no longer difficult. Now you can just buy a replacement light bulb that fits right in the socket. The bulb is called a BA9s. They come in different colors. You can get white, red, blue, green etc. White works great for the speedo and tach. White also works for the bulbs in the pilot box, but you can get red for the oil light, blue for the high beam and green for the neutral light if you want.

LED's use less power than regular bulbs and are sometimes (not always) brighter. I would say that's the main thing, the bulbs are usually bright enough but once in awhile they are not as bright as one might expect.

Replacement bulbs for tail lights are easy too. Just get an 1157. It should pop right in and work. Being that this is a light that other drivers see, it's important to get a very bright one. I like 1157's that have at least 45 LED's on them. The more, the better. Of course the more LED's the more expensive the light is.

An easy source for finding LED's is E-bay. There have been a few bulbs I bought from E-bay vendors that were not very bright and one of them failed within days. And once I bought an 1157 LED that would not fit into the socket. I think it might work for a car's tail light but the shape of the base would not fit into the socket on any of my motorcycles.

One thing I have not tackled is putting LED's in turn signals. Reading the SOHC forums, many have had problems with getting the turn signals to blink because of the light load. Regular flashers won't work because the LED's don't work correctly with the relays in the flashers. So people installing the LED turn signal lights have to change the relays too or figure out other things to do. And then there's the brightness factor too.

I'll wait on LED lights for my turn signals until it gets a bit easier to do.

Monday, October 3, 2011

Sunday, June 26, 2011

Clubmans on the Supersport

I sold the Honda recently. The new owner is a younger guy and he wanted some help fixing the Honda up how he wants it. So it's still at my house even though it's sold. He wants clubman handlebars.

Today I got to work on it. The first task was to grind a wire passage in the left control switches. Reason: the stock handlebars have holes where the wiring goes through them from switches to the center of the bar. The clubman bars are not drilled for internal wiring.

I had a spare left control switch so I worked on it and left the switch on the stock handlebar intact. It took quite awhile for me to grind a smooth gap big enough for the wires to go through. It's important not to grind into the wiring in the switches. The right switches were newer, I replaced them about a year ago and they actually had a gap built in for external wiring. This was not a feature on the original switches.

Next, removing the stock handlebars, disconnecting the throttle cables and the cafe mirrors. I bolted on the clubmans and got to work installing the switches on both sides along with the front brake master cylinder. The shorter bars resulted in excess throttle cable and hydraulic brake line, which had to be routed out so that the controls would work properly without binding. Another concern was making sure the switches on the handlebars would not bang on the gas tank at full lock.

With the bars on and the controls hooked up, next came the wiring. Here's where I ran into a snag. The left switches were from a different model CB, maybe a CB500 or CB550k. There are 11 wires coming from the switches and I think nine of them matched the wiring harness. The other two wires had similar colors but you only need to have one wire in the wrong socket to screw things up. At first, the headlight wasn't working. I moved the wires around a bit and then the headlight worked. But when I checked the turn signals, flipping the right signal would also cause the left signal AND the tail light to blink. And the same problem when flipping the left turn signal switch.

This is where I slowed down, counted the wires and identified the "suspect" wires where I wasn't sure if they were matching up correctly. A few more plugs and unplugs and it was figured out. Then I took some colored electrician's tape and color coded the wires for the next guy.

Here's how the bike looks with clubmans:

What do you think, is this a good look? Back in the day I would have liked it. Now, I think a set of CB400F bars (drilled for internal wiring) or a set of superbike bars would look better. And feel better.

The Honda has a new owner, so we'll let him have it his way.

Today I got to work on it. The first task was to grind a wire passage in the left control switches. Reason: the stock handlebars have holes where the wiring goes through them from switches to the center of the bar. The clubman bars are not drilled for internal wiring.

I had a spare left control switch so I worked on it and left the switch on the stock handlebar intact. It took quite awhile for me to grind a smooth gap big enough for the wires to go through. It's important not to grind into the wiring in the switches. The right switches were newer, I replaced them about a year ago and they actually had a gap built in for external wiring. This was not a feature on the original switches.

Next, removing the stock handlebars, disconnecting the throttle cables and the cafe mirrors. I bolted on the clubmans and got to work installing the switches on both sides along with the front brake master cylinder. The shorter bars resulted in excess throttle cable and hydraulic brake line, which had to be routed out so that the controls would work properly without binding. Another concern was making sure the switches on the handlebars would not bang on the gas tank at full lock.

With the bars on and the controls hooked up, next came the wiring. Here's where I ran into a snag. The left switches were from a different model CB, maybe a CB500 or CB550k. There are 11 wires coming from the switches and I think nine of them matched the wiring harness. The other two wires had similar colors but you only need to have one wire in the wrong socket to screw things up. At first, the headlight wasn't working. I moved the wires around a bit and then the headlight worked. But when I checked the turn signals, flipping the right signal would also cause the left signal AND the tail light to blink. And the same problem when flipping the left turn signal switch.

This is where I slowed down, counted the wires and identified the "suspect" wires where I wasn't sure if they were matching up correctly. A few more plugs and unplugs and it was figured out. Then I took some colored electrician's tape and color coded the wires for the next guy.

Here's how the bike looks with clubmans:

What do you think, is this a good look? Back in the day I would have liked it. Now, I think a set of CB400F bars (drilled for internal wiring) or a set of superbike bars would look better. And feel better.

The Honda has a new owner, so we'll let him have it his way.

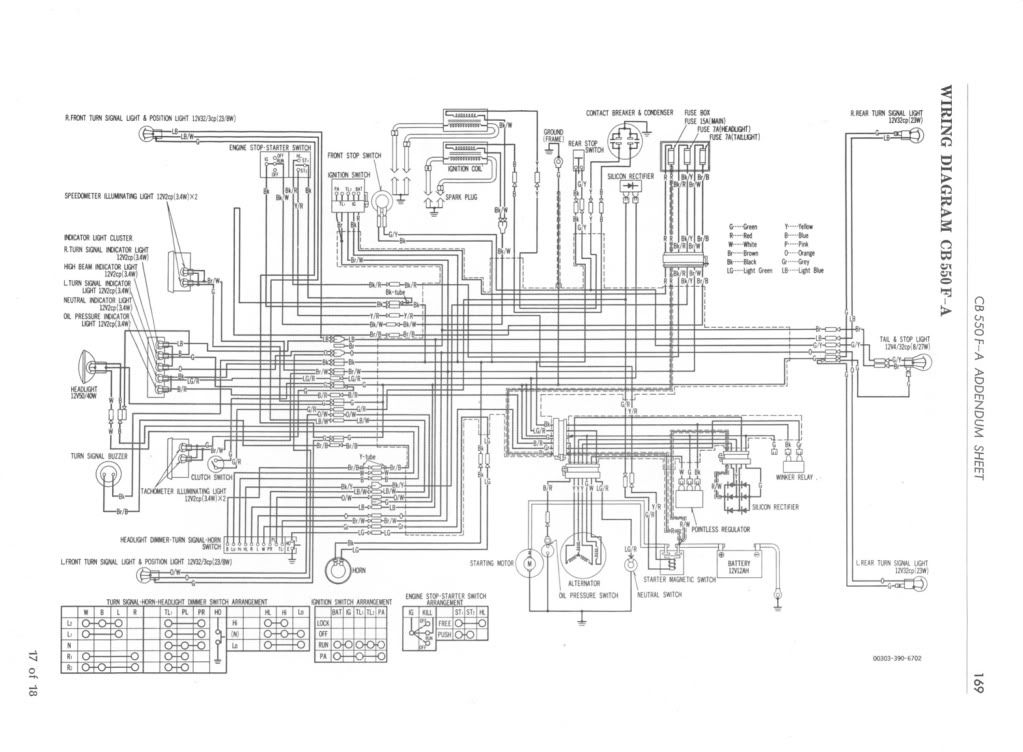

CB550F wiring diagram

Thursday, February 24, 2011

Fixing that elusive Honda CB brake squeal - really!

Just about anyone who owns a 70's Honda CB (350, 400F, 450, 500, 550, 750 - did I miss any?) knows these brakes tend to squeal. Honda builds some great machines and they get credit for being one of the first motorcycle manufacturers to put a disc brake on their street bikes. This disc brake design leaves something to be desired though.

I've been riding my CB550F around the island and enjoying it, EXCEPT when using the brakes. That squeal is annoying, even with ear plugs on. The sound can be modulated by varying brake lever pressure. But let's face it, when we're using the brakes we just want to concentrate on stopping and not noise levels.

So I had been doing this and that upgrading the brakes and hoping to get rid of that noise. Some of the upgrades included a new brake piston (Kevin 400F's from the sohc4 forum) made out of a hard plastic that will not corrode, Ferodo brake pads from the old days with asbestos braking material along with the master cylinder and new braided lower line mentioned in earlier posts.

The brake's stopping performance has been great! Just that sound...

So here's what I recently did attempting to fix the problem:

I believe the high temp grease layer between the caliper piston and the pad kept the noise away (for awhile). That is, until some of the layer squeezed out from between the piston and the pad. So I took the caliper apart again, put disc brake quiet on the back of this (brake piston-side) pad, let it dry thoroughly and placed it back in the caliper. The idea was letting the disc brake quiet dry thoroughly before reinstalling would help it set up on the back of the pad so it wouldn't squeeze out. It took another week until I had time to ride the Honda and I'm happy to report no more brake squeal.

I've been riding my CB550F around the island and enjoying it, EXCEPT when using the brakes. That squeal is annoying, even with ear plugs on. The sound can be modulated by varying brake lever pressure. But let's face it, when we're using the brakes we just want to concentrate on stopping and not noise levels.

So I had been doing this and that upgrading the brakes and hoping to get rid of that noise. Some of the upgrades included a new brake piston (Kevin 400F's from the sohc4 forum) made out of a hard plastic that will not corrode, Ferodo brake pads from the old days with asbestos braking material along with the master cylinder and new braided lower line mentioned in earlier posts.

The brake's stopping performance has been great! Just that sound...

So here's what I recently did attempting to fix the problem:

- Read through numerous posts on the Sohc4.net forum about brake squeal.

- Bought some high temp grease, cleaned the outboard brake pad off and coated its metal surfaces (not the brake pad material) then reinstalled it.

- Put "disc brake quiet" on the back of the inboard brake pad.

- Rode around with a loud brake squeal, except for just a few times here and there when it went away.

- Removed the arm that holds the disc brake pad assembly.

- Lubricated the pivot pin and o-rings with the high temp grease.

- Reassembled and lubricated the adjustment screw that aligns the brake pads to the disc.

- Cleaned off the brake pad that I had already lubricated with high temp grease and then lubricated it with that same grease AGAIN (on the metal surfaces and not the pad material).

- Used 150 grit sandpaper and scratched up the surfaces of the brake pads. Also gently chamfered the pads on the side where the disc contacts them first (the side closer to the motor).

- Lightly sanded the outboard side of the disc brake with the 150 grit sandpaper.

I believe the high temp grease layer between the caliper piston and the pad kept the noise away (for awhile). That is, until some of the layer squeezed out from between the piston and the pad. So I took the caliper apart again, put disc brake quiet on the back of this (brake piston-side) pad, let it dry thoroughly and placed it back in the caliper. The idea was letting the disc brake quiet dry thoroughly before reinstalling would help it set up on the back of the pad so it wouldn't squeeze out. It took another week until I had time to ride the Honda and I'm happy to report no more brake squeal.

Subscribe to:

Posts (Atom)