- The starter and the headlight weren't working. Both of those are connected via the handlebar switch. I took the switch apart, cleaned it up and put it back together. Still no go. Splurged and bought a new switch (costs about $100). That fixed the headlight problem but still the starter wasn't working.

- The left side crank seal was leaking! Why did this happen? It didn't leak before the engine came apart! I am guessing that the time the crank was out of the engine (about six months) caused it to leak. The seal was leaking right where it contacts the crank. If it were leaking around the crankcase joint it might have been possible to seal it up with permatex or something.

Tuesday, August 31, 2010

Ready to ride

Monday, July 12, 2010

CB550 Ups and Downs

The muffler was really easy to install - three bolts. The clamp at the headpipe junction, the bolt at the muffler and the connecting strap that goes to the passenger footpegs. That's it.

The more I look at the Honda the more I like it. There have been a lot of problems, in the end I think it will be worth it. I'm hoping to get the new carb boots and a few other pieces within a couple of weeks so I can actually ride this baby on the open road!

Friday, July 2, 2010

My CB550 started today!

It's been months and the victory arrived today! I've been working on the Honda in my spare time for the last couple of days trying to get some details sorted out. When I reinstalled the wiring harness, the only thing that would work was the tail light. A member of the SOHC4.NET forum suggested I check the wiring right at the point where the ignition plugs into the harness. I disconnected the wiring and hotwired it. The lights came on. Thus I knew the ignition wasn't getting a good connection. I cleaned the terminals and carefully plugged them back in. Then I checked to see if the ignition worked before I bolted it back to the triple clamp. The lights worked and I put it all back together.

It's been months and the victory arrived today! I've been working on the Honda in my spare time for the last couple of days trying to get some details sorted out. When I reinstalled the wiring harness, the only thing that would work was the tail light. A member of the SOHC4.NET forum suggested I check the wiring right at the point where the ignition plugs into the harness. I disconnected the wiring and hotwired it. The lights came on. Thus I knew the ignition wasn't getting a good connection. I cleaned the terminals and carefully plugged them back in. Then I checked to see if the ignition worked before I bolted it back to the triple clamp. The lights worked and I put it all back together.Secure the wiring harness to the frame; 3) Put the airbox back on; 4) Put a new muffler on.

Tuesday, June 22, 2010

Let's take the motor apart again

The first picture shows the second piston ring. The mark on it says "STD 3". The second picture shows the top and the oil ring. Click on the photos for larger pics and you can see the marks better. That's the mark indicating "this side up" when installing them on the piston.

The first picture shows the second piston ring. The mark on it says "STD 3". The second picture shows the top and the oil ring. Click on the photos for larger pics and you can see the marks better. That's the mark indicating "this side up" when installing them on the piston.Why a 3? Probably because this is a 3mm overbore kit for CB500 motors. I'm using it on a CB550, making it a 1/2mm overbore.

I spent a Sunday late morning and all afternoon, taking the motor apart down to the pistons, checking the rings, reinstalling and putting the motor back together. Good think I did this now, because about half of the top rings and oil rings were upside down as odds would predict.

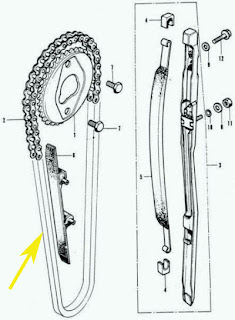

I had some problems getting the cam chain on once again. At least this time I figured out how to slacken up the chain tensioner to get that sprocket and chain in place on the cam. Turn the little screw on the tensioner to the left to get the most slack. Don't try forcing the sprocket onto the cam if there's not enough slack, you might end up stripping the threads on the bolt!

So the motor is back together and we're getting close to startup day.

Saturday, June 12, 2010

Changing a tire

Wednesday, June 9, 2010

Putting the motor back together

Another Important Lesson with CB550 Motors

Wednesday, May 26, 2010

Important info when working on a CB550 motor

Here are some observations.

When I split the cases a couple of months ago I put the transmission parts in a bag. Last week when I started putting the motor back together, the bearing race seen in the photo fell off and out fell some tiny needle bearings! Usually needle bearings are "caged," that is they are held together in a race. This set of bearings has a race but they are not attached. After sitting around for months the oil keeping them in place drained out and the bearings scattered. Most of them were easy to find but I had to hunt around the carport to find the last two on the floor. There are a total of 16 needle bearings. I packed them with automotive grease to keep them together when I put the race back on the transmission main shaft.

Another item to keep an eye on is the kickstart shaft. It's easy to take motors apart and harder to remember how they go back together. I installed the two transmission shafts and saw that the countershaft was engaging the kickstart shaft. Then I was trying to remember how these two shafts should work together. When I turned the countershaft it would wind up the kickstart shaft. That's okay for starting the engine with the kickstarter but we don't want the two gears to mesh all the time.